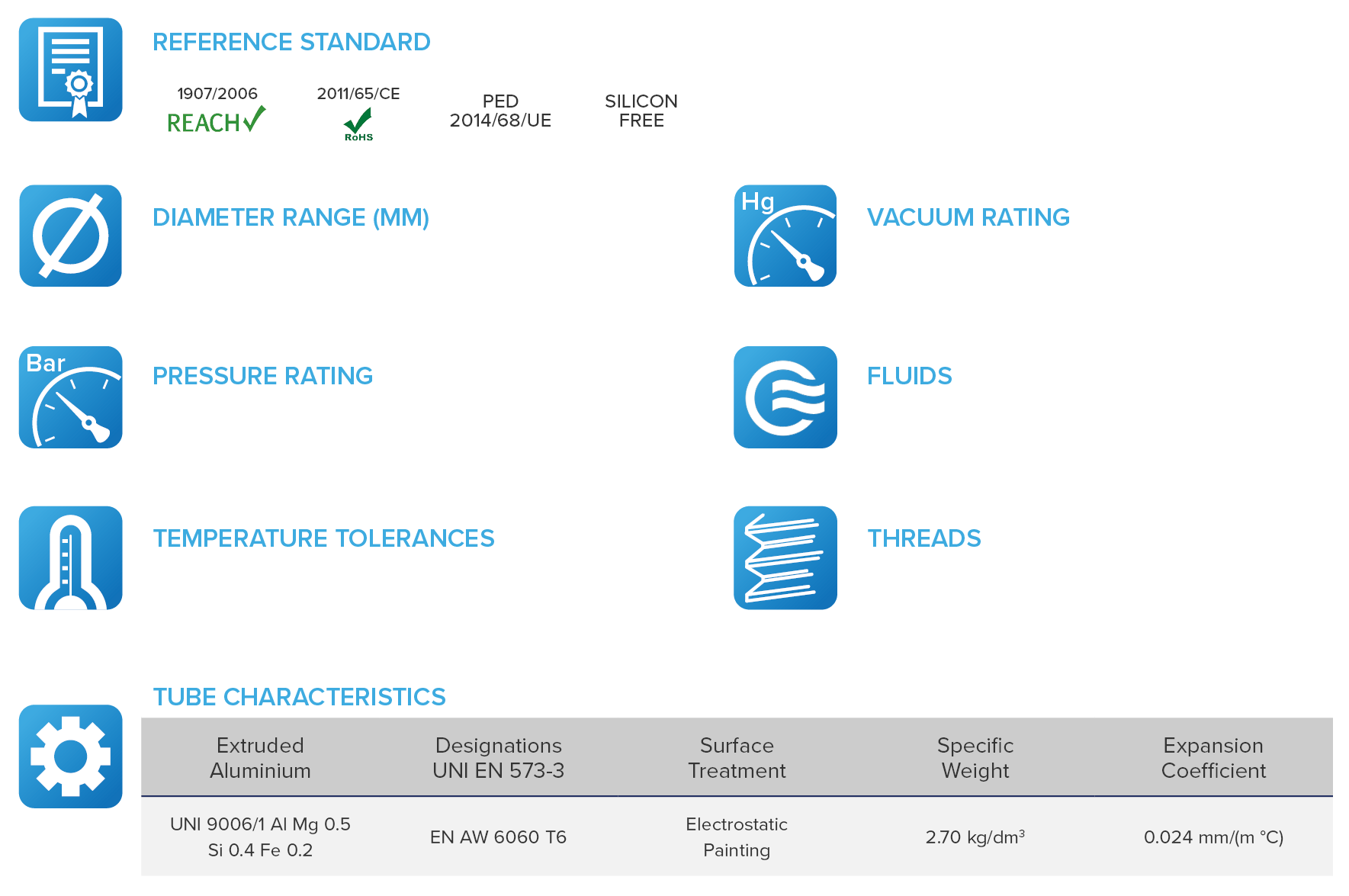

Infinity products adhere to a range of reference standards. We ensure the technical specifications of our products fall in line with these standards and are manufactured to the highest quality standards.

ASSEMBLING Ø20 - Ø63 PIPEWORK & FITTINGS

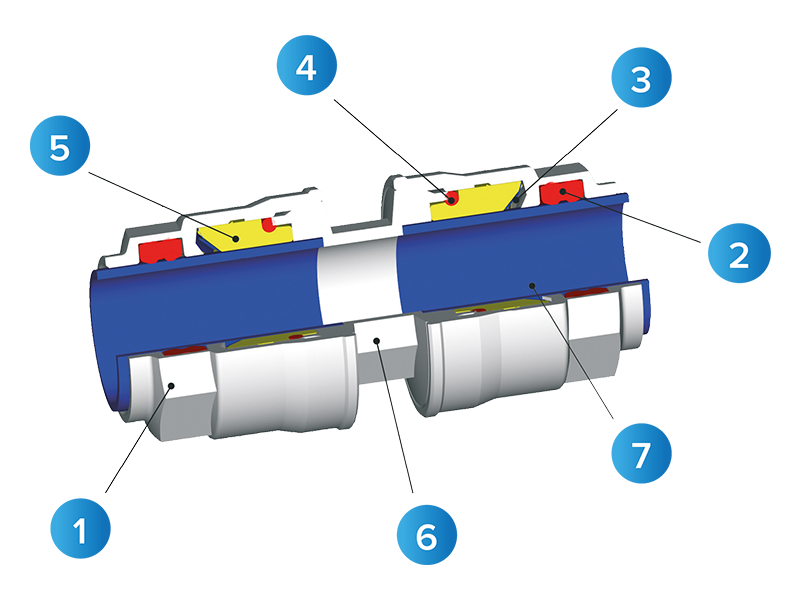

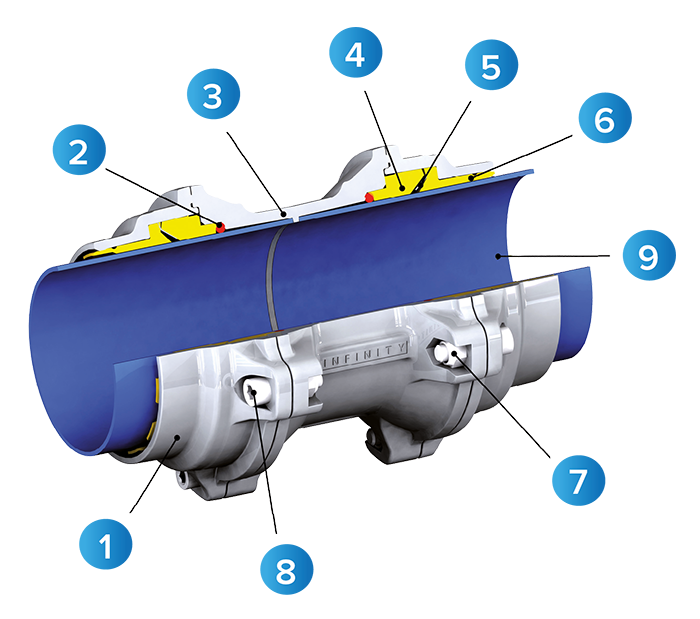

COMPONENT PARTS AND MATERIALS

Nut | Nickel-plated brass (aluminium Ø63)

Seal | NBR

Clamping Washer | INOX AISI 301

O-ring | NBR

Safety Ring | Technopolymeric

Body | Nickel-plated brass (aluminium Ø63)

Extruded Aluminium Tube | Calibrated and powder coated

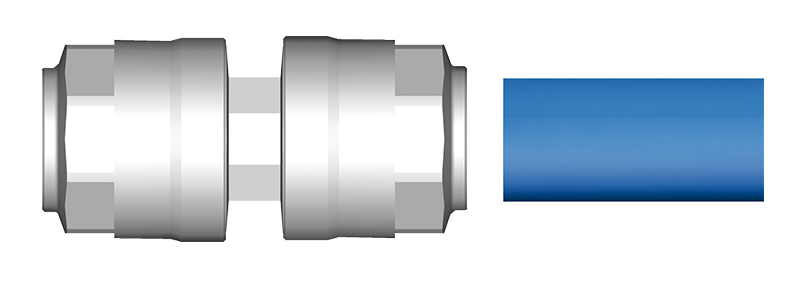

ASSEMBLING Ø20 | Ø25 | Ø32 | Ø40

- Fittings of Ø20 | Ø25 | Ø32 | Ø40 are pre-assembled tubes 4m and 6m pre-coated, calibrated burred.

- Push tube into the fitting for automatic connection.

- In case of fitting disassembling, use the torques as in the chart to re-assemble the fitting.

Click here to download our assembling guide

| Ø mm | Torque specifications |

| 20 | 3 Nm |

| 25 | 3 Nm |

| 32 | 4 Nm |

| 40 | 6.5 Nm |

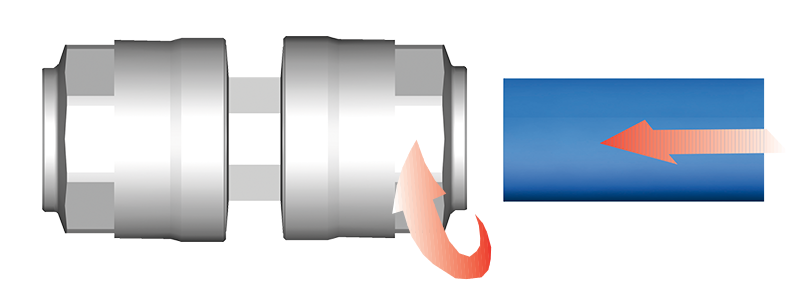

ASSEMBLING Ø50 | Ø63

- Fittings of Ø50 | Ø63 are pre-assembled with nut untwisted to help tube connection. Tubes of 4m and 6m are pre-coated, calibrated and burred.

- Push tube into the fitting for connection and tighten the nut using torques as in the chart.

Click here to download our assembling guide

| Ø mm | Torque specifications |

| 50 | 45 Nm |

| 63 | 85 Nm |

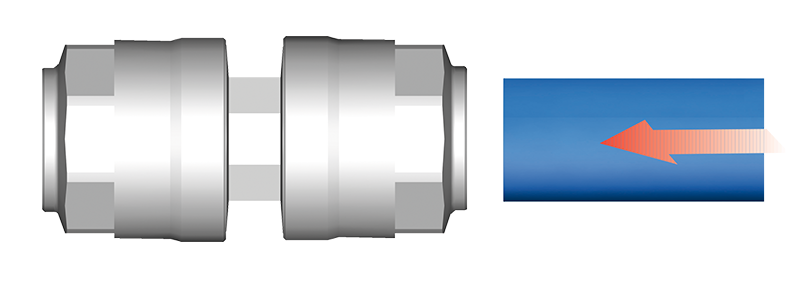

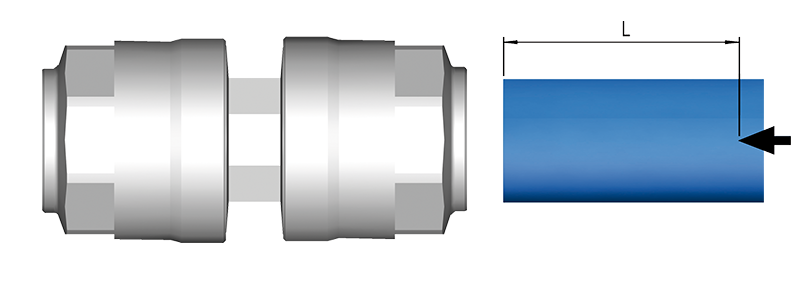

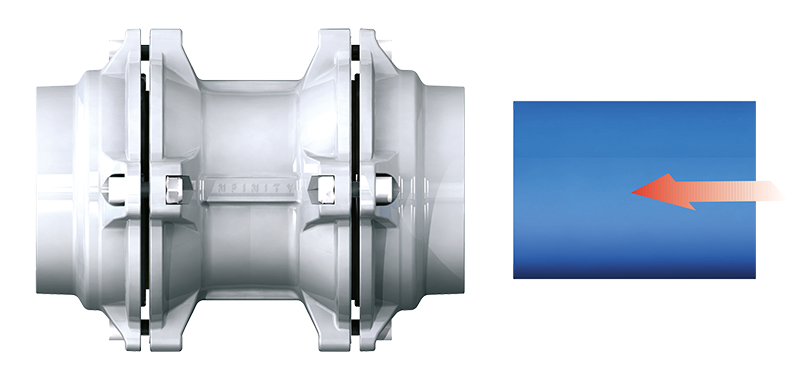

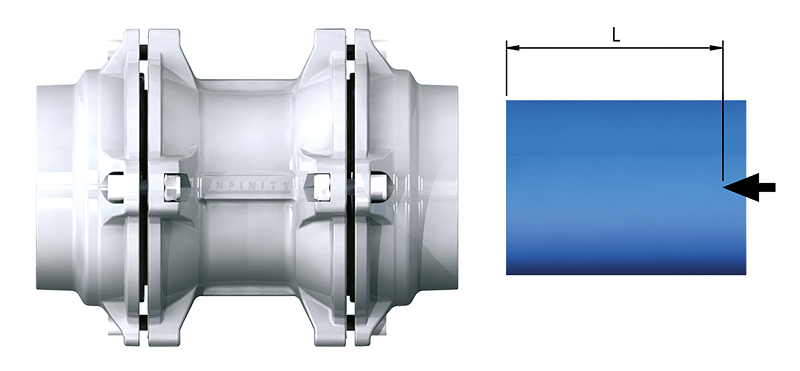

TUBE CONNECTION

The correct tube connection of tube is confirmed by the position of the arrow pre-stamp. If you need to cut the tube, mark the distance of tube to insert in the fitting.

| Ø mm | L mm |

| 20 | 31.5 |

| 25 | 38.5 |

| 32 | 46 |

| 40 | 52 |

| 50 | 57.5 |

| 63 | 63.5 |

ASSEMBLING Ø80 - Ø168 PIPEWORK & FITTINGS

COMPONENT PARTS AND MATERIALS

Nut | Aluminium with finished surface treatment

O-ring | NBR

Body | Aluminium with finished surface treatment

Safety Ring | Technopolymeric

Clamping Washer | AISI 301

Tube-guide Ring | Technopolymeric

Self-locking Nut | Zinc-plated steel

TCEI Screw | Zinc-plated steel

Extruded Aluminium Tube | Calibrated and powder coated

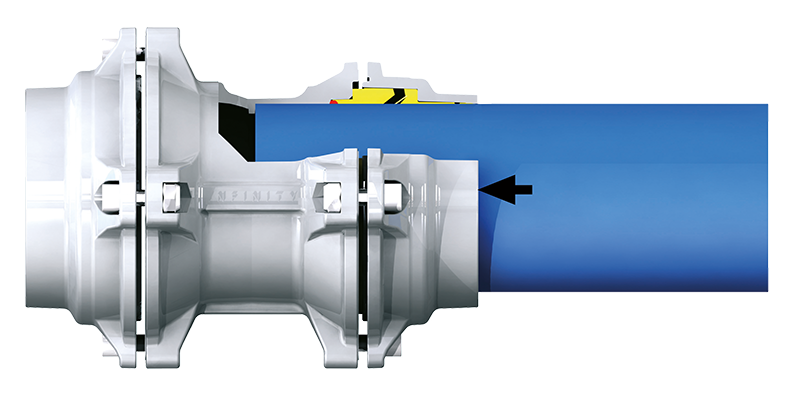

ASSEMBLING Ø80 | Ø110 | Ø168

- Fittings of Ø80 | Ø110 | Ø168 are pre-assembled with four screws untwisted to help tube connection. Tubes of 4m and 6m are pre-coated, calibrated and burred.

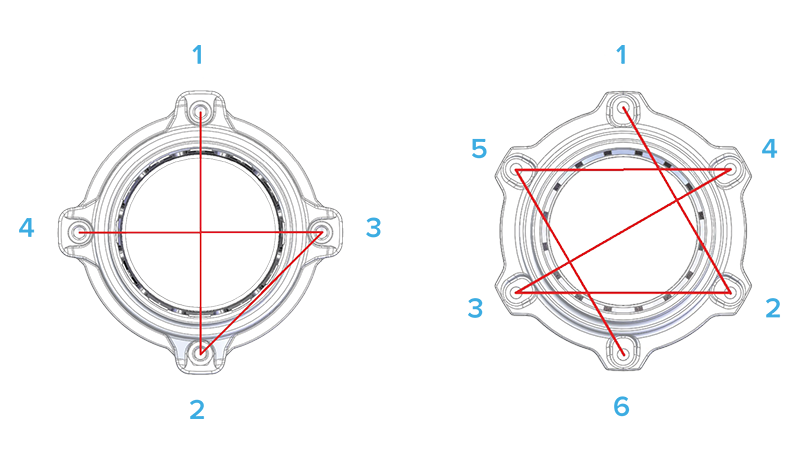

Push tube into the fitting for automatic connection and tighten in the recommended sequences below. Tighten the nut using torques as in the chart.

| Ø mm | Torque specifications |

| 80 | 30 Nm |

| 110 | 30 Nm |

| 168 | 60 Nm |

TUBE CONNECTION

The correct tube connection of tube is confirmed by the position of the arrow pre-stamp. If you need to cut the tube, mark the distance of tube to insert in the fitting.

| Ø mm | L mm |

| 80 | 91 |

| 110 | 125.5 |

| 168 | 193 |