Create an Infinity Account to take advantage of our quick ordering process, account dashboard and dedicated pricing.

Already a valued customer? Click the button below to log in and order your pipework, fittings, tooling and accessories.

INFINITE POSSIBILITES

Infinity Pipework Systems

Infinity Pipework is the exclusive UK agent for the lightweight, push-fit, modular Infinity range. We have brought to market a sleek alternative to older systems - it is fully adjustable and reusable making it ideal for future expansion.

INFINITE SOLUTIONS

Superior air flow performance

Our pipework and fittings are an advanced solution for use in air, vacuum, nitrogen generation and other inert gas applications. Installation is straightforward, thanks to a small range of easy-to-use tools and accessories.

INFINITE EXPERTISE

Project management support

In addition to pipework design and install we offer industry leading advice. Our consultant team will recommend the most effective and suitable air system layout for your specific needs and application.

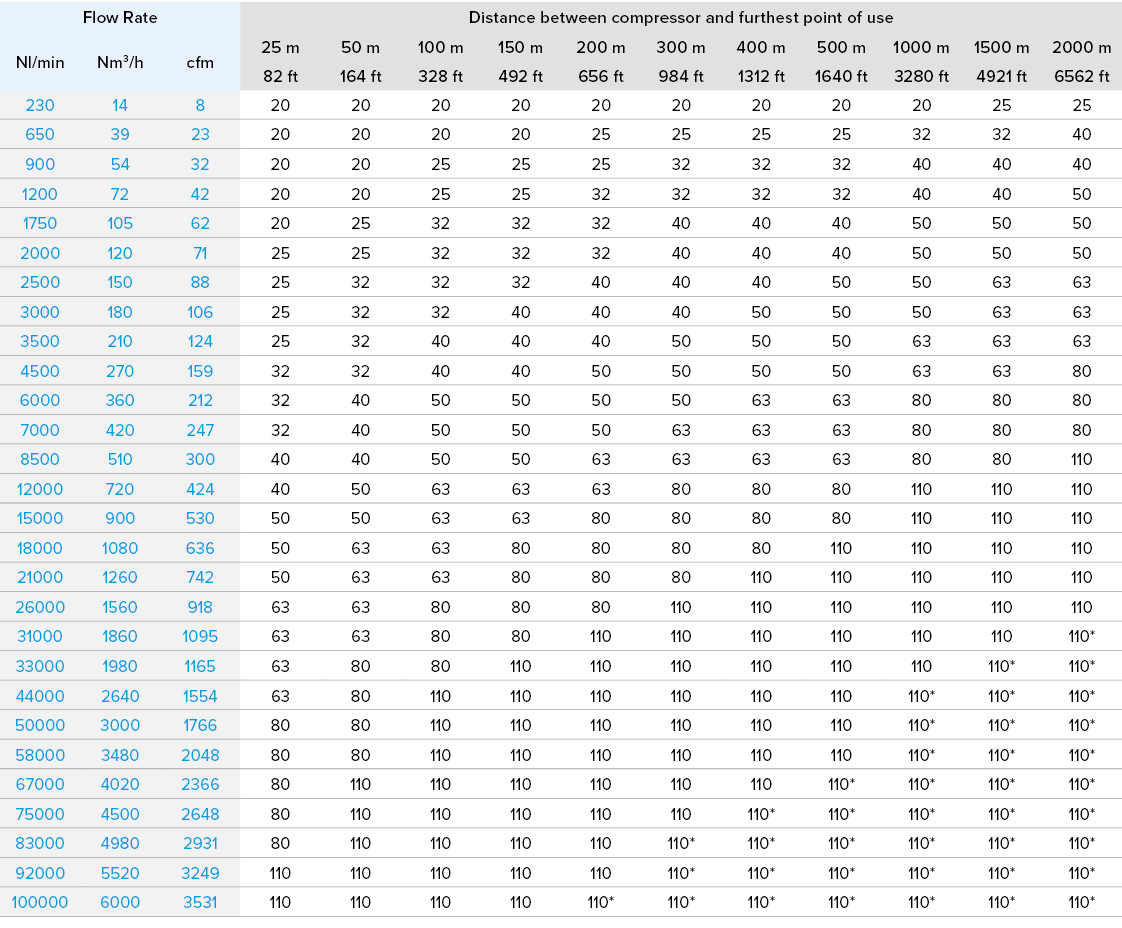

Pipe Sizing

Pipe Sizing

Use the table below to determine the pipe sizing you require for your installation:

- Select the flow rate of the compressor

- Select the distance between the compressor and the furthest most point of the installation.

- Cross the lines of flow rate and distance columns to establish the size of the pipe you require.

- Example - 42cfm compressor with a maximum pipework distance of 200 metres (to the furthest usage point) will require a 32mm pipework system.

Flow Rate Distance between the Compressor and the furthest usage point

Pressure 7 bar - Total pressure drop 4%

• = Pressure drop is greater than 4%

Click here to download our sizing guide

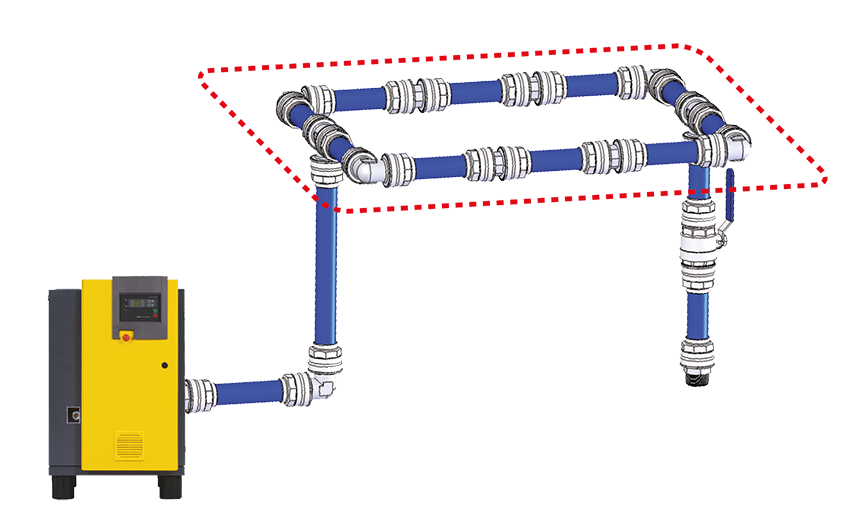

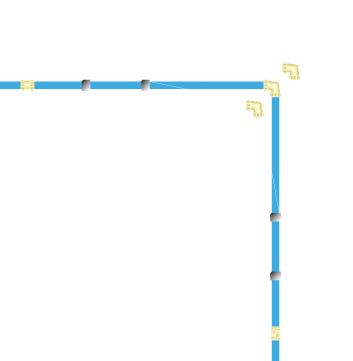

LOOP SYSTEM

Ring main

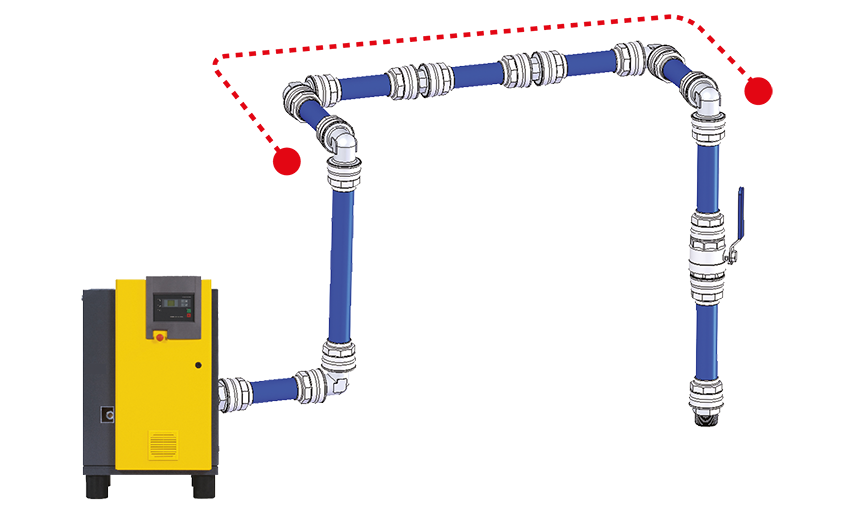

LINEAR SYSTEM

Header

INDICATIVE FLOW RATES

Compressors to 7 Bar

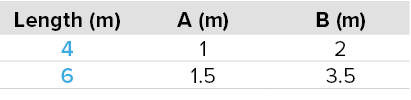

EXPANSION & CONTRACTION DUE TO HEAT

To calculate the linear expansion - contraction we can use the following formula: ΔL = ΔT x L x a

ΔL = Linear expansion - contraction in mm

ΔT = Heat variation between the operating temperature and the installation one at °C

L = Tube length in m

a = Linear expansion factor, for the aluminium is 0.024 mm/m °C

The installation has to be positioned giving consideration at the two ends to free space which permits the expansion - contraction and supports have to be fixed as shown in the illustration:

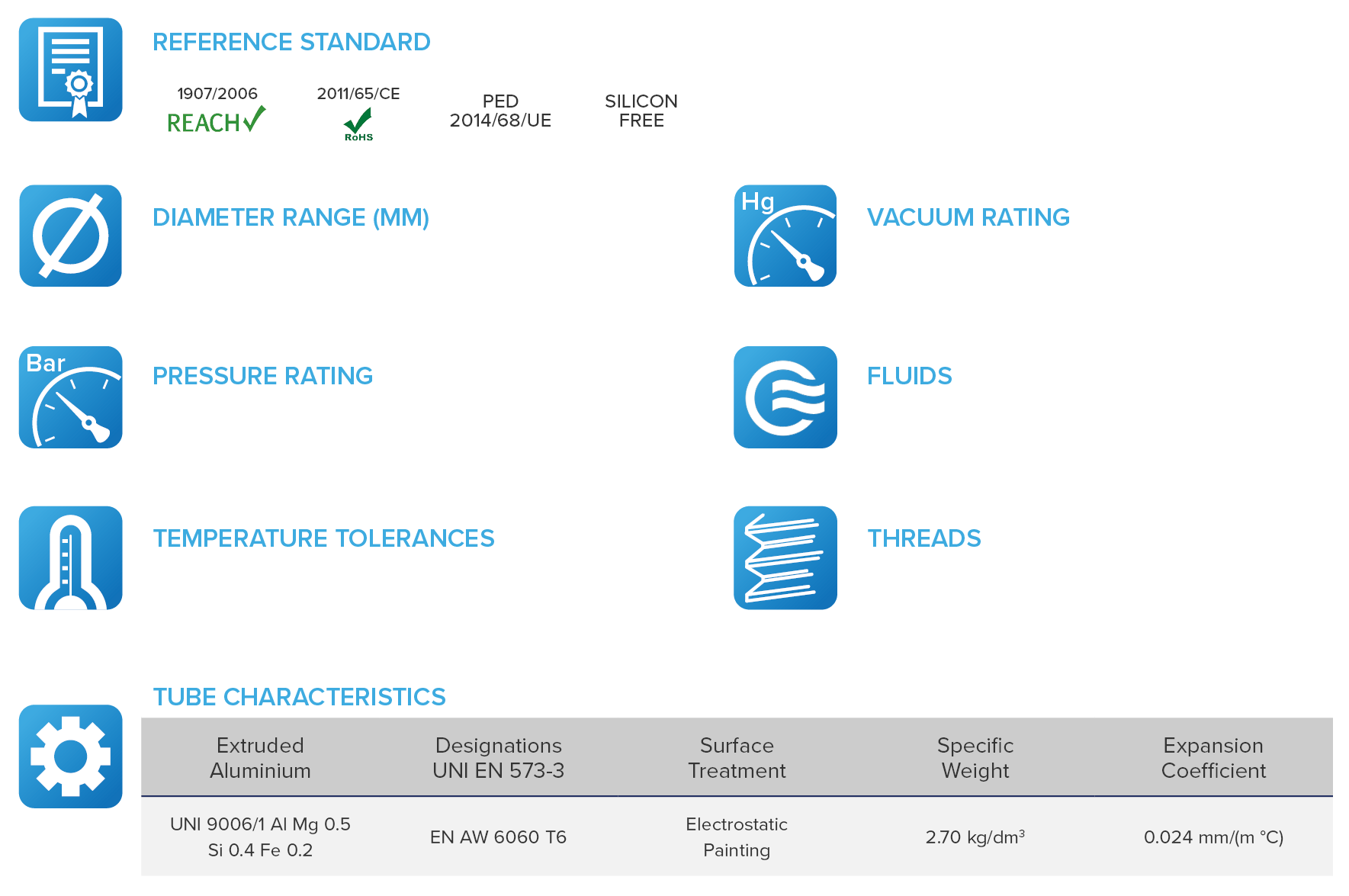

Installation Guides

Infinity products adhere to a range of reference standards. We ensure the technical specifications of our products fall in line with these standards and are manufactured to the highest quality standards.

ASSEMBLING Ø20 - Ø63 PIPEWORK & FITTINGS

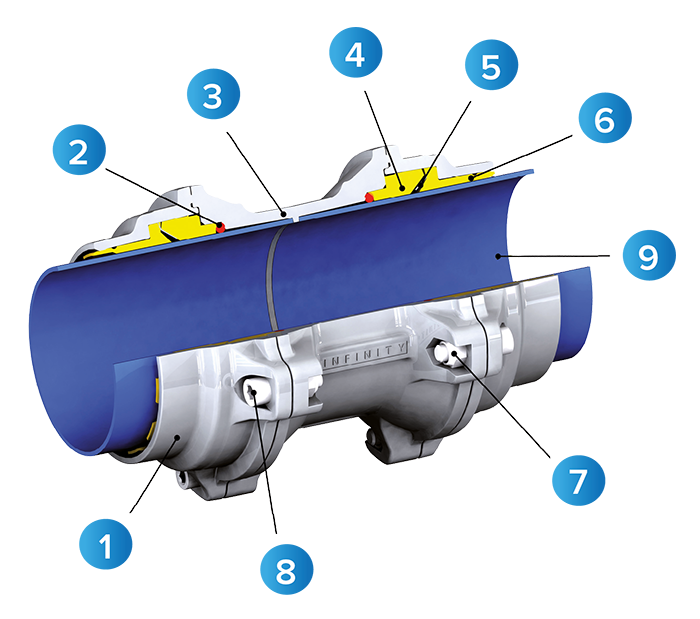

COMPONENT PARTS AND MATERIALS

Nut | Nickel-plated brass (aluminium Ø63)

Seal | NBR

Clamping Washer | INOX AISI 301

O-ring | NBR

Safety Ring | Technopolymeric

Body | Nickel-plated brass (aluminium Ø63)

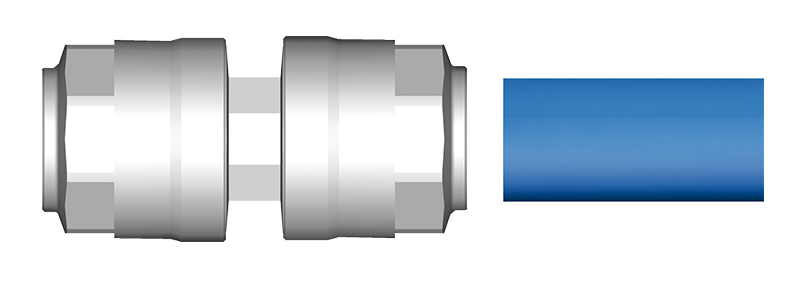

Extruded Aluminium Tube | Calibrated and powder coated

ASSEMBLING Ø20 | Ø25 | Ø32 | Ø40

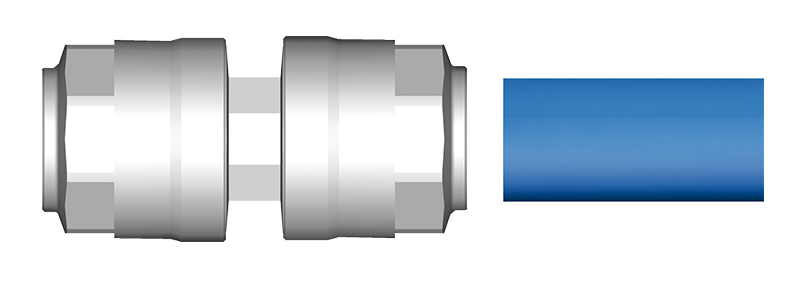

- Fittings of Ø20 | Ø25 | Ø32 | Ø40 are pre-assembled. Tubes of 4m and 6m are pre-coated, calibrated and burred.

- Push tube into the fitting for automatic connection.

- In case of fitting disassembling, use the torques as in the chart to re-assemble the fitting.

Click here to download our assembling guide

| Ø mm | Torque specifications |

| 20 | 3 Nm |

| 25 | 3 Nm |

| 32 | 4 Nm |

| 40 | 6.5 Nm |

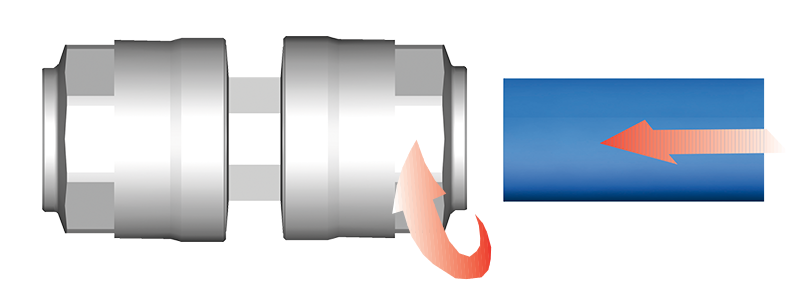

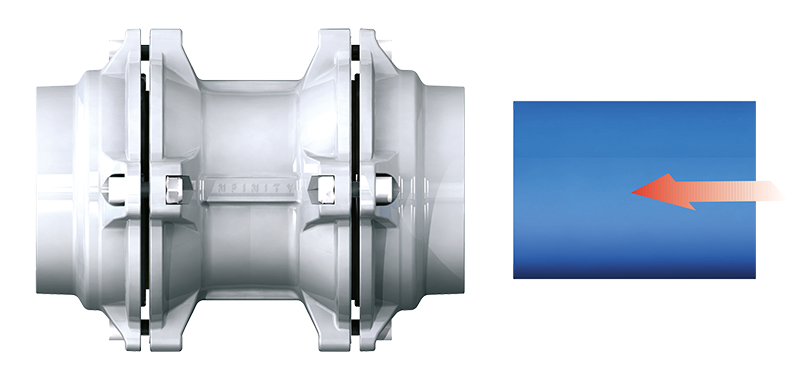

ASSEMBLING Ø50 | Ø63

- Fittings of Ø50 | Ø63 are pre-assembled with nut untwisted to help tube connection. Tubes of 4m and 6m are pre-coated, calibrated and burred.

- Push tube into the fitting for connection and tighten the nut using torques as in the chart.

Click here to download our assembling guide

| Ø mm | Torque specifications |

| 50 | 45 Nm |

| 63 | 85 Nm |

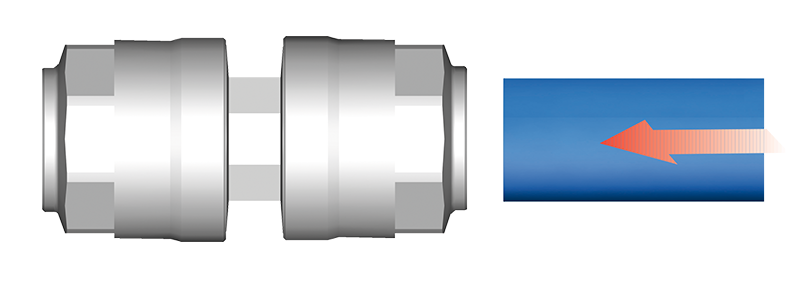

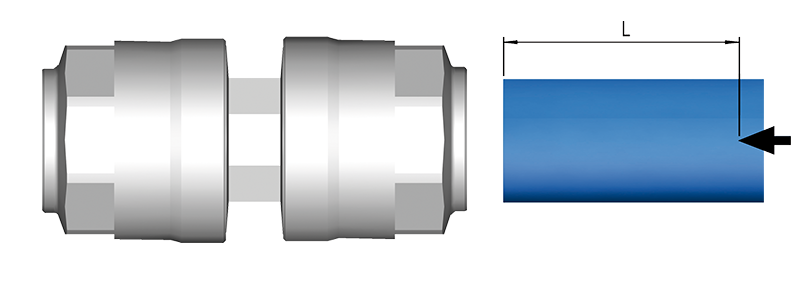

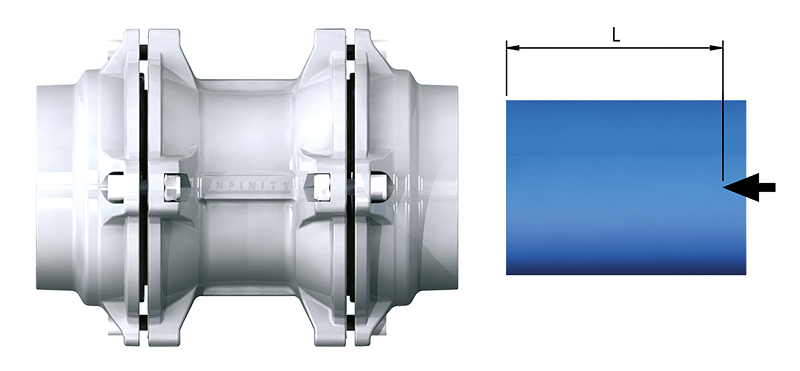

TUBE CONNECTION

The correct tube connection of tube is confirmed by the position of the arrow pre-stamp. If you need to cut the tube, mark the distance of tube to insert in the fitting.

| Ø mm | L mm |

| 20 | 31.5 |

| 25 | 38.5 |

| 32 | 46 |

| 40 | 52 |

| 50 | 57.5 |

| 63 | 63.5 |

ASSEMBLING Ø80 - Ø168 PIPEWORK & FITTINGS

COMPONENT PARTS AND MATERIALS

Nut | Aluminium with finished surface treatment

O-ring | NBR

Body | Aluminium with finished surface treatment

Safety Ring | Technopolymeric

Clamping Washer | AISI 301

Tube-guide Ring | Technopolymeric

Self-locking Nut | Zinc-plated steel

TCEI Screw | Zinc-plated steel

Extruded Aluminium Tube | Calibrated and powder coated

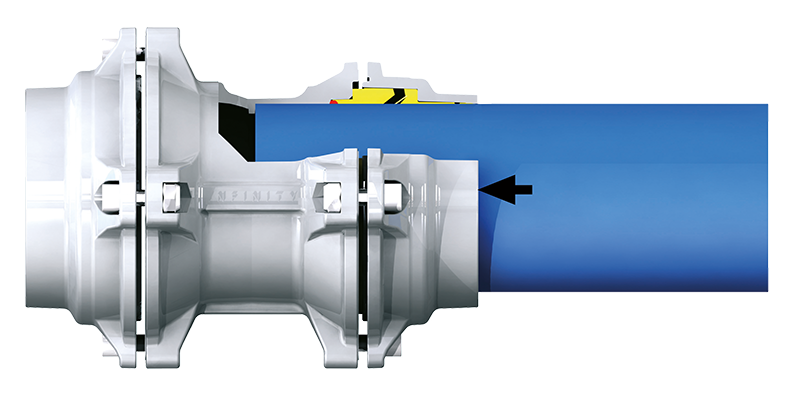

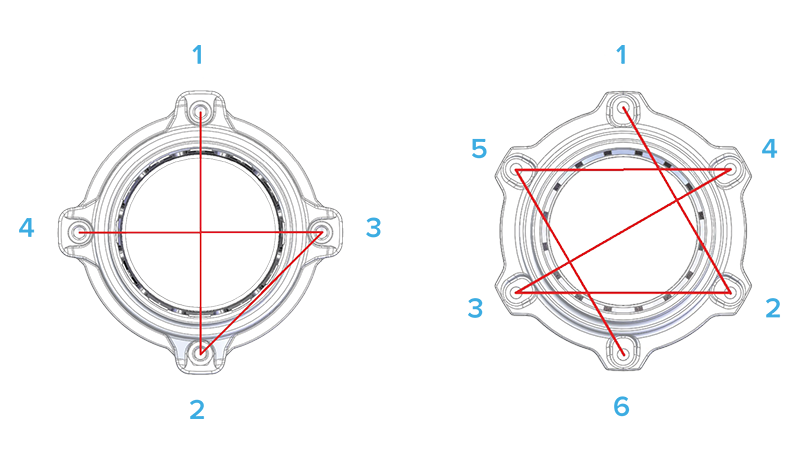

ASSEMBLING Ø80 | Ø110 | Ø168

- Fittings of Ø80 | Ø110 | Ø168 are pre-assembled with four screws untwisted to help tube connection. Tubes of 4m and 6m are pre-coated, calibrated and burred.

- Push tube into the fitting for automatic connection and tighten in the recommended sequences below. Tighten the nut using torques as in the chart.

Click here to download our assembling guide

| Ø mm | Torque specifications |

| 80 | 30 Nm |

| 110 | 30 Nm |

| 168 | 60 Nm |

TUBE CONNECTION

The correct tube connection of tube is confirmed by the position of the arrow pre-stamp. If you need to cut the tube, mark the distance of tube to insert in the fitting.

| Ø mm | L mm |

| 80 | 91 |

| 110 | 125.5 |

| 168 | 193 |