Infinity pipework installation expertise

Our pipework installation service extends far beyond the simple and traditional installation. It provides our clients with a professional system, fully fit for purpose.

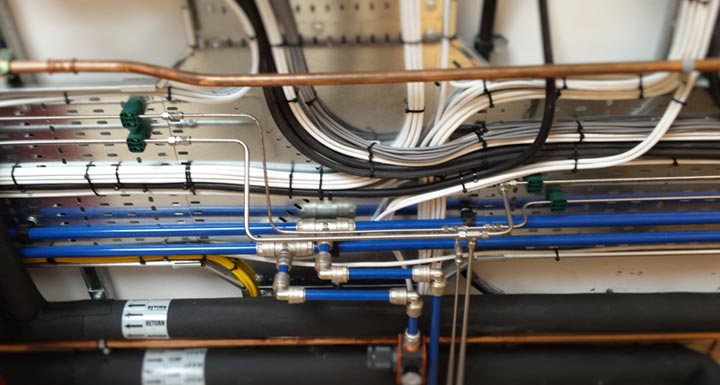

Infinity Pipework are the exclusive UK agents for the lightweight, push-fit Infinity range. Utilising this tubing product, we have brought to market a sleek and aesthetically pleasing alternative to older systems. This provides our clients with a professional pipework installation, fully fit for purpose.

Installers of the Infinity system operate across the UK and are made up of highly skilled technicians who provide efficient and productive systems.

Our technical teams are happy to work to the clients brief, where the initial design can be accepted in many formats. Formats we accept include CAD, right the way through to conceptual layout ideas and final installation approval.

All Infinity installations are carried out in accordance with the Pressure Systems Regulations 2000 and are completed by our own experienced, trained engineers. Following installation, we are available to conduct regular maintenance and air quality checks. This is to ensure your system is leak-free and the air remains clean.

Our team of Infinity Pipework installation engineers will:

- Travel to any location in the UK

- Install a leak-free, efficient and effective system

- Conduct regular maintenance and quality checks

- Construct a new system or modify an existing air line construction

Our installation team is on hand to support you ...

Infinity Pipework in-house fitters and engineers are experienced in all types of air-line pipework installation.

Whether a simple modification or an entirely new air distribution system, our team is on hand to support you. All Infinity installations are carried out in accordance with the latest BCAS (British Compressed Air Society) 'best practice' guidelines and The Pressure Systems Regulations 2000.

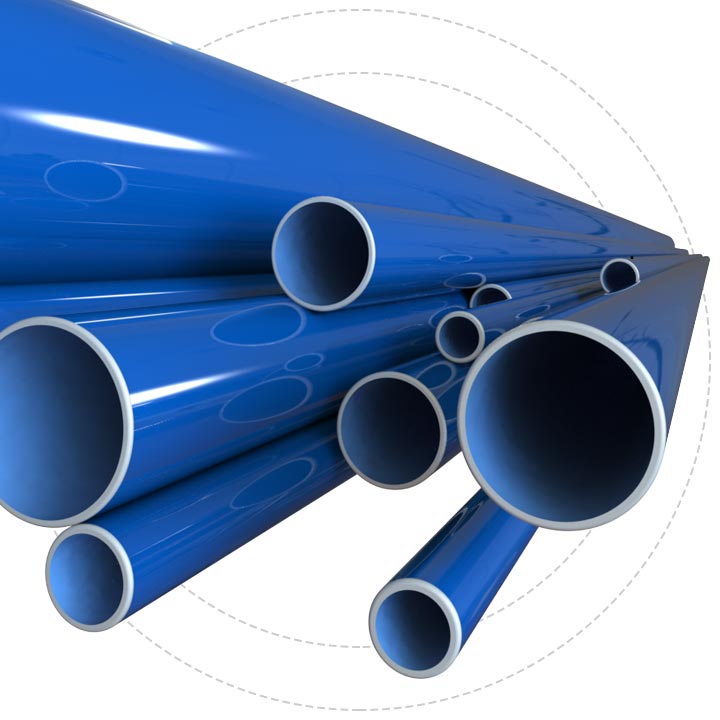

Aluminium pipe is inherently stronger than plastic pipes providing greater rigidity and saving further install time as only half the mounting brackets are required.

Our preferred Infinity product provides aluminium, energy efficient smooth bore tubing from 20mm to 110mm with extremely high flow rates. Infinity fittings are simply pushed together for an automatic connection without the need for soldering, threading or gluing. As a result, your system is constructed efficiently.

We are a company with vast experience in recommending and installing the best material to suit a specific need or application. In addition to aluminium tubing, we also install galvanised steel (medium and heavy weight), stainless steel, copper, ABS and plastic.

Do you have an installation enquiry? Get in touch with the Infinity support team ...

Leak Detection - Air Leak Test Surveys

It is estimated that 30% of the compressed air that is generated in the UK is wasted through leakage. Rectifying your leaks can significantly reduce your operating costs.

Infinity Leak Detection Surveys identify and pin-point the location of leaks from an air or gas system. Our service identifies where the leaks are and in most cases the cost of each leak. Following installation, a full leak detection survey will be completed to ensure the system we have installed is fully air tight.

Our service also illustrates the potential savings that can be made; to achieve this level of detail in our surveys we use state of the art ultrasonic leak detectors.

These devices identify the smallest of leaks, even those which are inaudible to the human ear. During the survey, each leak is allocated a unique number and listed on the summary sheet. A label, detailing the following information is fixed to the system as close to the source as possible.

This label includes: a leak number, severity of leak, area on site, location in area and relevant engineer comments.

Written Schemes of Examination

Under the Pressure Systems Safety Regulations 2000, a written scheme of examination is required for most pressure systems; only very small systems are exempt. This contains information about items of plant equipment forming part of a pressure system, operate under pressure and contain relevant fluid.

The term 'relevant fluid' is defined in the regulations and covers compressed or liquified gas, including air. Air is defined against a pressure measurement greater than 0.5 bar (approximately 7 PSI) above atmospheric temperature. For pressurised hot water to be considered relevant it must be above 110 ºC with steam at any pressure.

The written examination document should be drawn up by a competent person/ company (as defined in the regulations). This person may or may not be the same competent person who advised the user or owner on the scope of the written scheme. That is where Infinity Pipework come in and we would be happy to assist you with further details on this topic.

If you are interested in an Infinity system, get in touch. We look forward to supporting your enquiry.